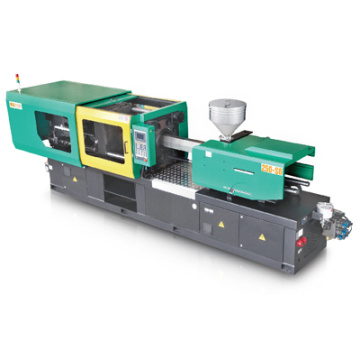

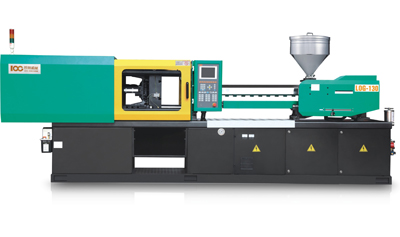

Specialized Plastic Injection Molding Machiness

Descripción del producto

Characterics:

1.High repeat precision

2.High injection speed

3.Super energy saving

Advantages:

● LOG250-S6 injection machine + 2 cavities injection mold,only spend electricity 11KWH/h,comparing to Japan injection machine's 38KWH/h,save about 70% energy.

● According to test result,this machine really can save 70% energy than normal plastic injection molding machine.

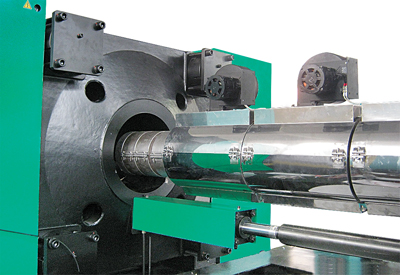

Thin Wall machine:

Characterics:

1.Equipped with optimalized hydraulic system,injection speed greatly improved

2.Optional injection accumulator , the injection speed may up to 500mm / s or more.

3 Matching with special dedicated fast screw, result in a higher plasticizing capacity.

4. Improved cylinder balance injection system.

5 Enhance actions such as pre-plasticizing, mold open/close and ejection etc.

6 highly rigid clamping structure to meet the requirements of high-speed high pressure, which will help extend the life of the die, significantly improve the accuracy of the product.

Advantages:

● High speed variable pump hydraulic system configuration, saving more than 30% of conventional machines.

● Dynamic templates and guide column with self-lubricating bearings, high cleanliness.

● Improving large sol motor configuration, enabling efficient quality plasticizers.

● High rigid template structure resist bending and result in low deformation.

● Synchronization Synchronization mold thimble, shorten the molding cycle.

● increased ejector force for rapid ejection of multi-cavity products.

● increase the cooling device,shorten the cooling time.

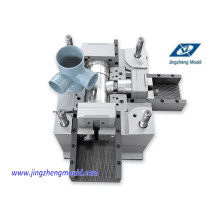

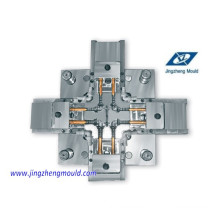

UPVC machine:

● air cooling device to control the reaction speed, temperature accurate. (Optional)

● new special screw design, fit UPVC material properties, result in stable plasticizing with good effect.

● widening security structure for placing long core pulling mold.

● automatic oil pump.

● can be installed auto-mode devices.

Advantages:

● special oplized for PVC,adopt chromed nozzle flange and nozzle, strong corrosion resistance.● High speed variable pump hydraulic system configuration, saving more than 30% of conventional machines.

● Improve large sol motor configuration, enabling efficient quality plasticizers.

● each cylinder air-cooled temperature control device alone, high temperature control accuracy.

● two sets of hydraulic core pulling device.

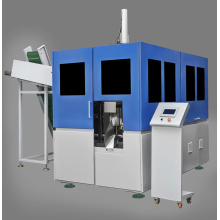

PET machine

Feathers:

● optimized screw design reduces the air content of the preform;

● excellent plasticlizing quality make preform color more evenly and forming more stable;

● According to preform product features, a number of structures configured are optimized to improve, caused higher productivity and more stable production process.

1, High speed variable pump hydraulic system configuration, saving more than 30% of conventional machines;

2, Improve a large sol motor configuration, enabling efficient high-quality plasticizers;

3, High rigid template structure resist bending and result in low deformation;

4, Increase the screw diameter to increase the injection volume;

5, Enlargen the trap blocks enhance the cooling effect.

Grupos de Producto : Máquina de moldeo por inyección

Premium Related Products